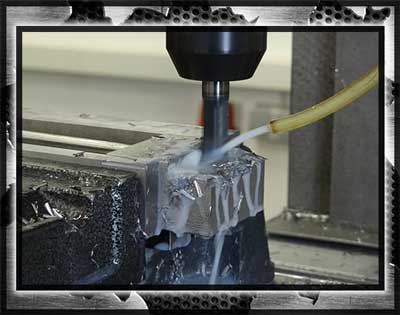

We integrated many improvements to many

of our customers existing machines and have worked

with their equipment manufactures to ensure these improvements meets our customer’s specifications.

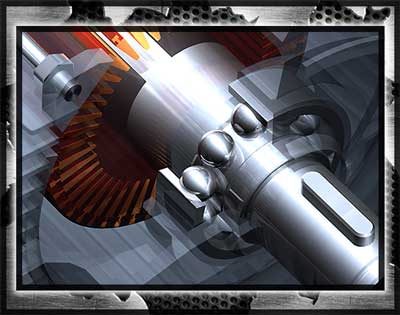

Our engineers will write the needed machine build specifications and work with your machine build company to ensure that these specifications are followed.

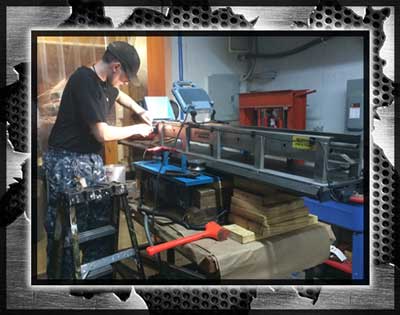

We will write the test plans needed to complete your CQV process.

Once this process is complete we will work with your operators to ensure that are trained on your startup process.

We will custom design and build complete machines to match your process and needs.